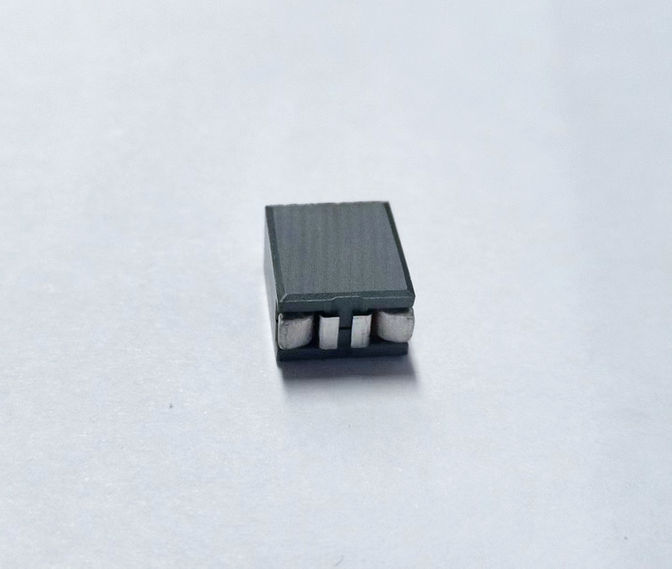

Power Bead Inductors

Compact, High-Current Solutions for Demanding Applications

GB International’s Power Bead Series inductors deliver compact, high-efficiency performance for today’s most demanding power electronics. Our catalog offers a wide range of inductance values, optimized thermal properties, and AEC-Q200 qualified options. Whether you need proven catalog parts or a custom design tailored to your application, our engineering team is here to help.

Benefits of GBI Power Bead Inductors

-

High Power Density: Compact designs that reduce board space while maintaining performance.

-

Thermal Efficiency: Excellent heat dissipation for reliable operation under continuous load.

-

Automotive & Industrial Grade: AEC-Q200 qualified options available for EV and mission-critical environments.

-

Flexible Range: Wide selection of inductance values and current capabilities.

-

Customizable: Options for tailored inductance, packaging, or encapsulation available upon request.

GBI PN | Comp PN | Manufacturer | Description | Inductance | Units | Frequency | Length (MM) | Width (MM) | Height (MM) |

|---|---|---|---|---|---|---|---|---|---|

12093-GR | NA | NA | power bead inductor | 160 | nH | 100KHZ/1V | 10.5 | 6.8 | 4.8 |

12094-GR | NA | NA | power bead inductor | 150 | nH | 100KHZ/1V | 10 | 7 | 10 |

12095-GR | HGPB1012-R10KC | Highlight | power bead inductor | 100 | nH | 100KHZ/1V | 10 | 6 | 12 |

12096-GR | NA | NA | power bead inductor | 100 | nH | 100KHZ/1V | 7 | 6.6 | 3.4 |

12105-GR | 744235110 | Wurth | CMC | 11 | uH | 100KHz/0.1V | 0.5 | 3.2 | 2.8 |

12106-GR | LQH32CH2R2M33L | Muratta | SMD Power Inductor | ||||||

12107-GR | B82559A5103A033 | TDK | Edge Wound Inductor | ||||||

12118-GR | PAD002-T764113S | Bourns | Isolation Transformer | ||||||

12124-GR | HM2103NL | Pulse | Transformer CMC | ||||||

12200-GR | NA | NA | power bead inductor | 140 | nH | 100KHZ/1V | 17 | 7 | 3.6 |

Applications

GB International power beads are engineered for:

-

Electric Vehicles (EV & Hybrid): Onboard chargers, DC-DC converters, inverters.

-

Industrial Systems: Power supplies, motor drives, renewable energy storage.

-

High-Density Electronics: Space-constrained layouts requiring efficient magnetic components.

-

Telecom & Networking: High-reliability inductors for power distribution and filtering.

Why Choose GB International

-

Dual-site production in the U.S. and China for scalability and cost efficiency.

-

Proven track record supporting OEMs, Tier-1 suppliers, and industrial leaders.

-

Flexible manufacturing for both low-volume prototyping and high-volume production.

-

Engineering support for design reviews, cost-reduction strategies, and compliance testing.

Ready to Find the Right Power Bead for Your Design?

Contact our engineering team for datasheets, samples, or a custom build.

Call: 607-785-0938 ext 129 | Email: customer.service@gbint.com